Understand what doing more with data looks like.

Use cases for Litmus Edge and case studies from clients around the world demonstrate real business impacts and IIoT in action.

IMPROVE

Throughput, Uptime, Yield, Time to Market + ROI

REDUCE

Scrap, Defects, Manual OEE + Downtime

Use Cases

A flexible and scalable industrial data platform that's easy to deploy and easier to use.

OT, IT and digital transformation engineers and leaders trust Litmus to help them make data more actionable in real time, make IIoT more accessible, mature into machine learning and improve efficiencies across the plants.

Industrial IoT

With Litmus Edge, manufacturers can connect to any asset in minutes, collect data and analyze it at the edge. They can also integrate with cloud and big data applications for advanced analytics and then run the models back at the edge for continuous improvement.

Smart Manufacturing

With an all-in-one edge platform that connects the dots, Litmus Edge can be deployed next to assets to collect, analyze, manage and integrate real-time data from the factory floor to meet business needs not only on the floor but across the entire organization.

Machine Learning

Through Litmus Edge and with third party apps, feed machine learning models with valuable, normalized and contextualized data, and complete the feedback loop by running the new models at the edge. With our own digital twins, Litmus also serves as the source of data so asset modeling and instances are working on the same platform.

Predictive Maintenance

Reduce unplanned downtime, increase efficiency and get more proactive across the enterprise. Real-time data can provide additional insight to supply chain and go-to-market teams for better planning and forecasting.

Condition Based Monitoring

Many industrial companies struggle to capture basic machine health data such as temperature, vibration, velocity and more. Litmus Edge helps you understand how assets are performing in real-time, collecting, normalizing and contextualizing all data from all PLCs, DCS, SCADA, historians and sensors.

OEE

Litmus Edge collects and analyzes asset data needed to dramatically simplify the calculation of OEE with out-of-the-box KPIs. OT and IT teams trust Litmus to deliver the critical data they need to improve manufacturing uptime, performance and quality scores.

IIoT Success Stories

We’re proud to share challenges, results, projects and initiatives that Litmus Edge and our team have played a role in.

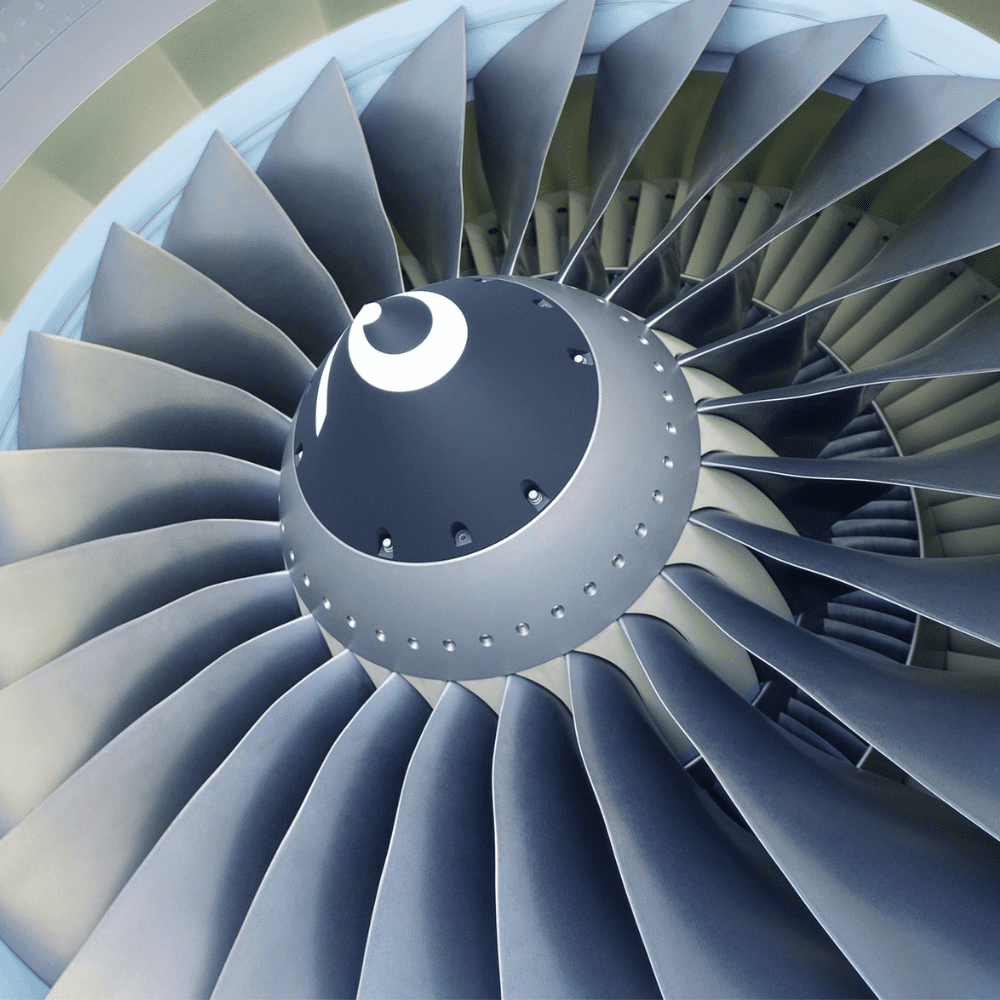

Aerospace Manufacturer Reduces Downtime and Improves OEE

Read More

Food Manufacturer Uses Agritech to Improve Crop Yield

Read More

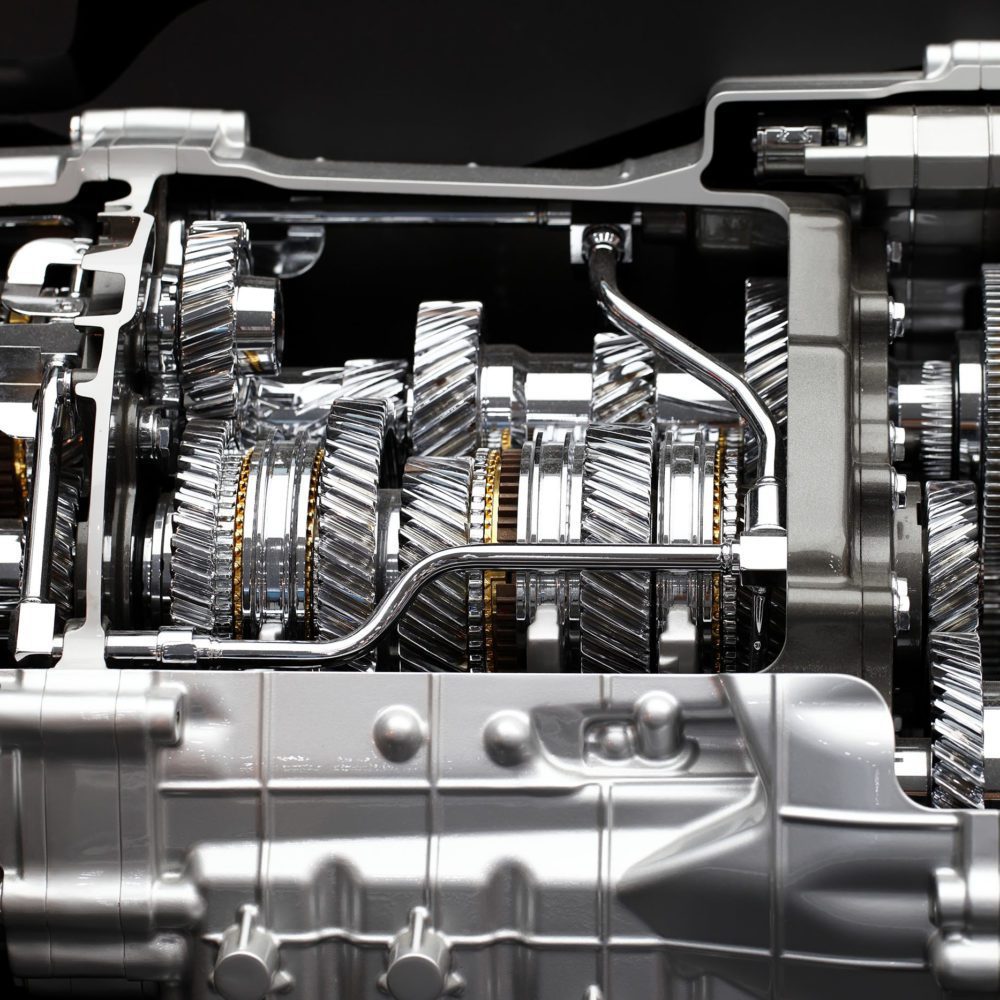

Automotive Supplier Digitizes Manual Workflow

Read More

Industrial Machinery Manufacturer Increases Profits with IIoT

Read More

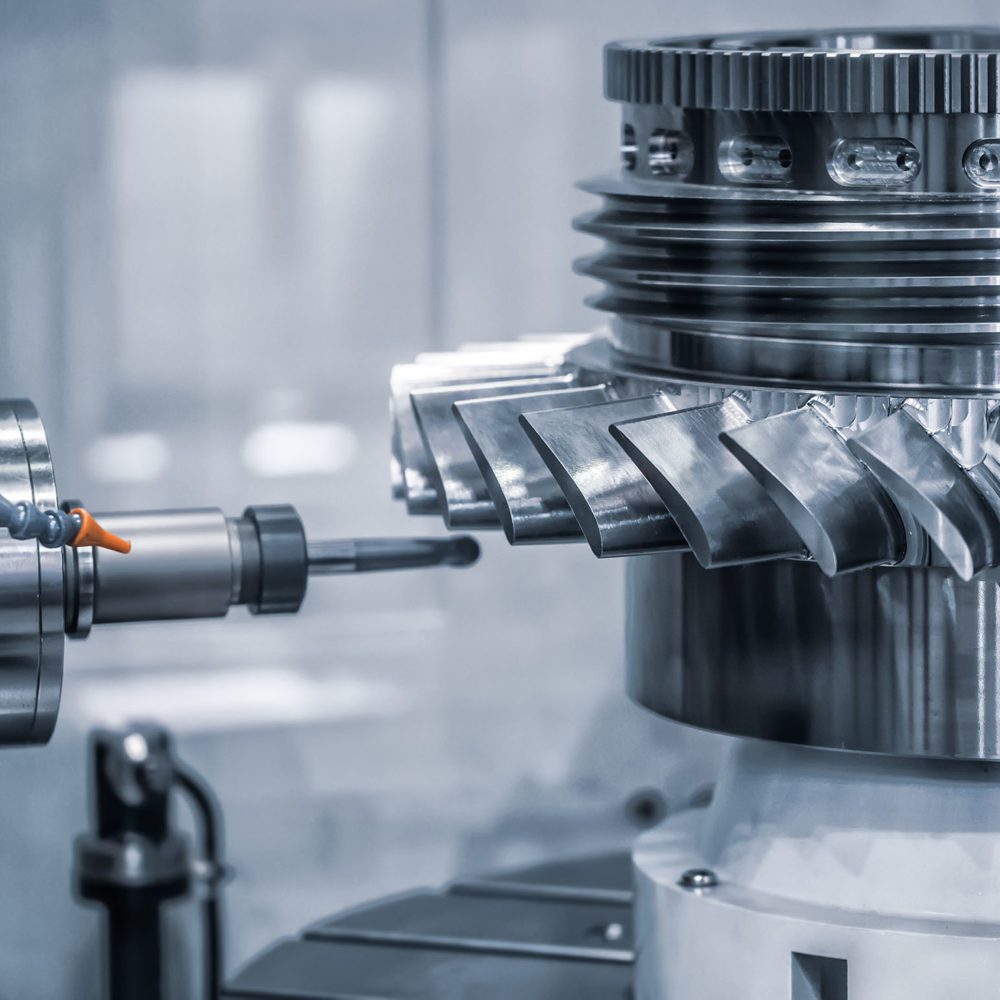

Tool Manufacturer Monitors CNC Machines for Quality Improvement

Read More

Cable Manufacturer Improves Quality and Reduces Manufacturing Costs With IIoT

Read More

Bottled Water Manufacturer Leverages OT Data to Improve Operations

Read More

Mining Company Augments SCADA with IoT Platform to Enable Predictive Maintenance

Read More

Food Manufacturer Achieves Complete Digital Transformation with Litmus

Read More